Forehearth Advanced Control

Conditioning is, besides the furnace, responsible for determining the glass quality, and this is what counts in the end.

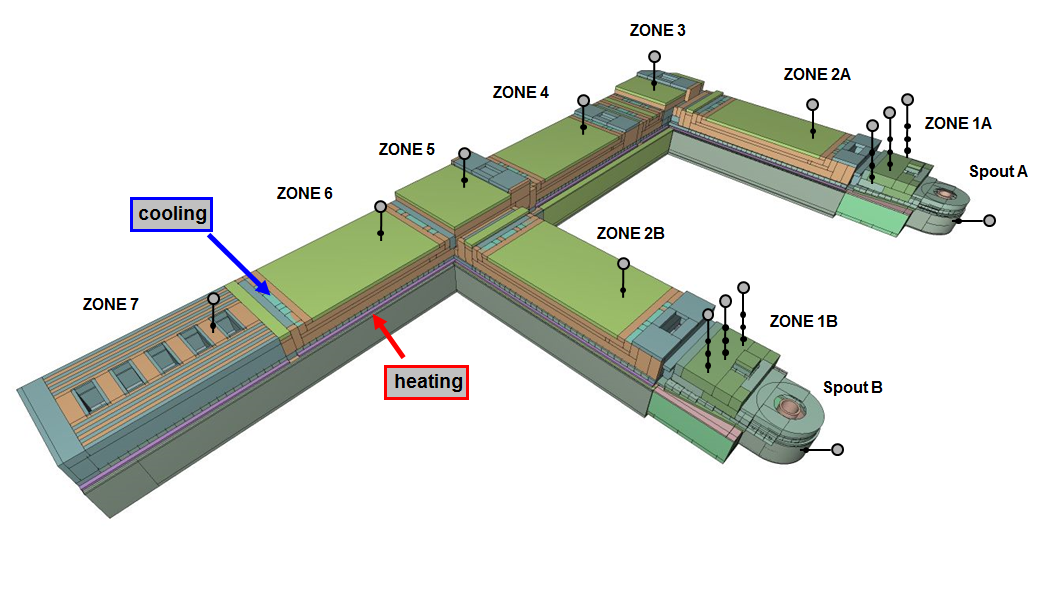

ES III™ can be used with any type of forehearth/feeder:

- Fossile

- Electrical

- Mixed: Fossile and Electrical

Specific Benefits:

- Temperature stability

- Improved thermal homogeneity before spout

- Gob weight stability

- Higher forming productivity

- Minimizing time for job changes

- Temperature stability

- Stability of spread, producing reduced nip loss

- Tweel operation minimization

- Stable delivery conditions

- Temperature stability

- Stability of glass conditioning before fiberizing

- Minimizing time for job changes

- Reduced defects and breakages

- Improved quality of fiber production (diameter)

- Stable delivery conditions

- Temperature stability

- Stability of glass conditioning before fiberizing

- Minimizing time for job changes

Example 1: ES III™ control of feeder job change

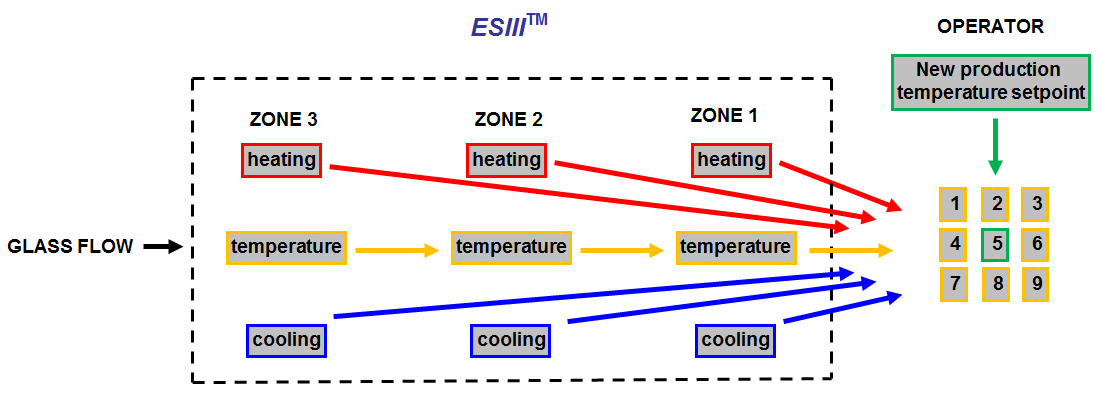

Operator only needs to specify new production temperature for the article (9-grid or spout).

ES III™ controls simultaneously all heatings and coolings of entire feeder in one controller, also during the job changes, to reach required new setpoint at optimal homogeneity.

ES III™ takes into account variations in upstream temperatures and various residence time of glass in feeder at different pulls to control 9-grid temperatures.

Example 2: ES III™ feeder setpoint control

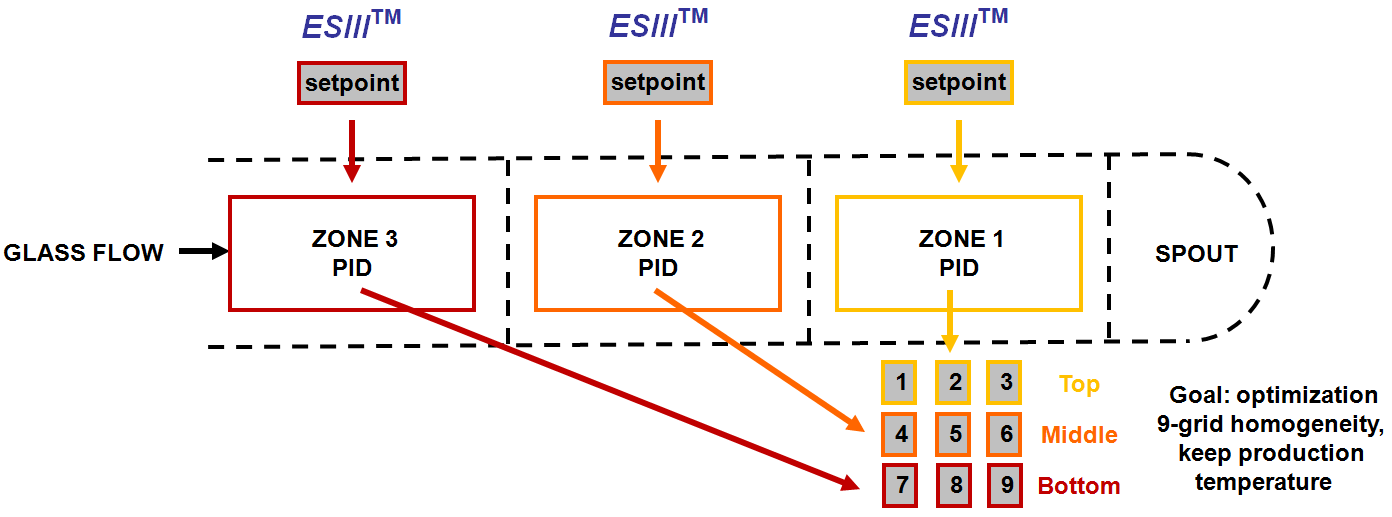

ES III™ adjusts setpoints continuously to improve homogeneity:

Zone 3 and 2 setpoints control 9-grid middle and bottom, Zone 1 setpoint controls 9-grid top.

PID still controls each zone separately to required setpoint (ES III™ / PID in cascade).

Result: ES III™ automatic 9-grid control

ES III™ automatic direct control of 9-grid process values after a setpoint increase.

Figure displays Middle Top, Bottom Left and Bottom Right temperatures.

Further Information:

-

Please contact us to receive more information, our latest presentation, or a quotation to purchase.