Glass Defects Analyses

GS offers analyses of defects in glass & bubble source studies, which include:

- Defect analysis – bubbles & stones, cords and others such as gall, knots, surface defects

- Bubble source identification procedure

- Classification of the sources according to mechanism of bubble generation

- Bubble features and estimated composition in the product -> identification

Our laboratory is equipped with latest technology including three Mass Spectrometers, SEM/EDX microprobe, various optical microscopes and very precise sample preparation equipment to address any melting, refining and forming defect problem in any kind of glass product.

It is the biggest world independent laboratory for glass defects.

Express delivery of results - 24 hours in terms of urgency

SGD performed an intensive bubble defect investigation analysis on one of our furnaces last year.

We did a statistical analysis that helped us to understand better the appearance of two types of bubbles.

We determined two main root causes and defined actions to reduce such defects when occurring.

The affordable GS defect analysis with their high quality and quick response is vital to keep a high yield in our high quality production.

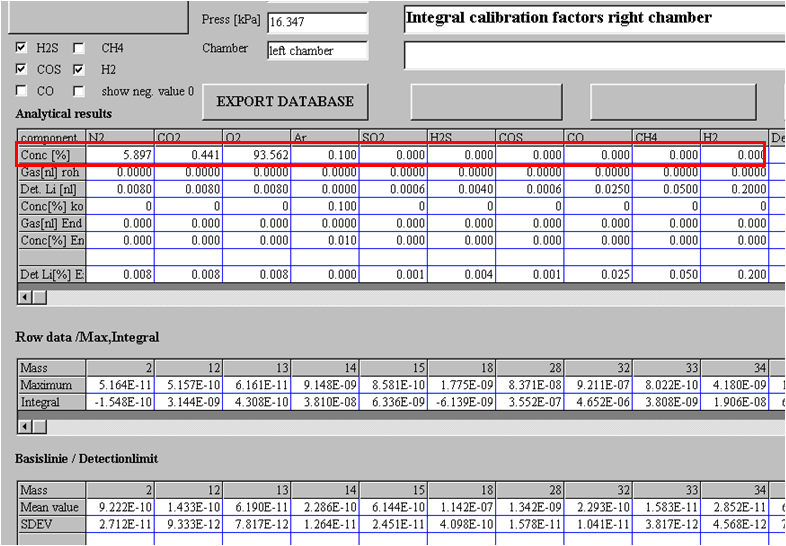

Example: Bubble Analysis

The graphic shows the analysis of a certain bubble.

Typical gases analyzed: O2, N2, CO2, SO2, Ar, H, COS, H2S, CO, H2, (H2O)

From the composition of the gases in the bubble, but also from its size, distribution in the product, intensity and internal pressure, it is possible to identify possible source of such defect. Operational information about the furnace and its construction may also help to be more specific in bubble source identification.

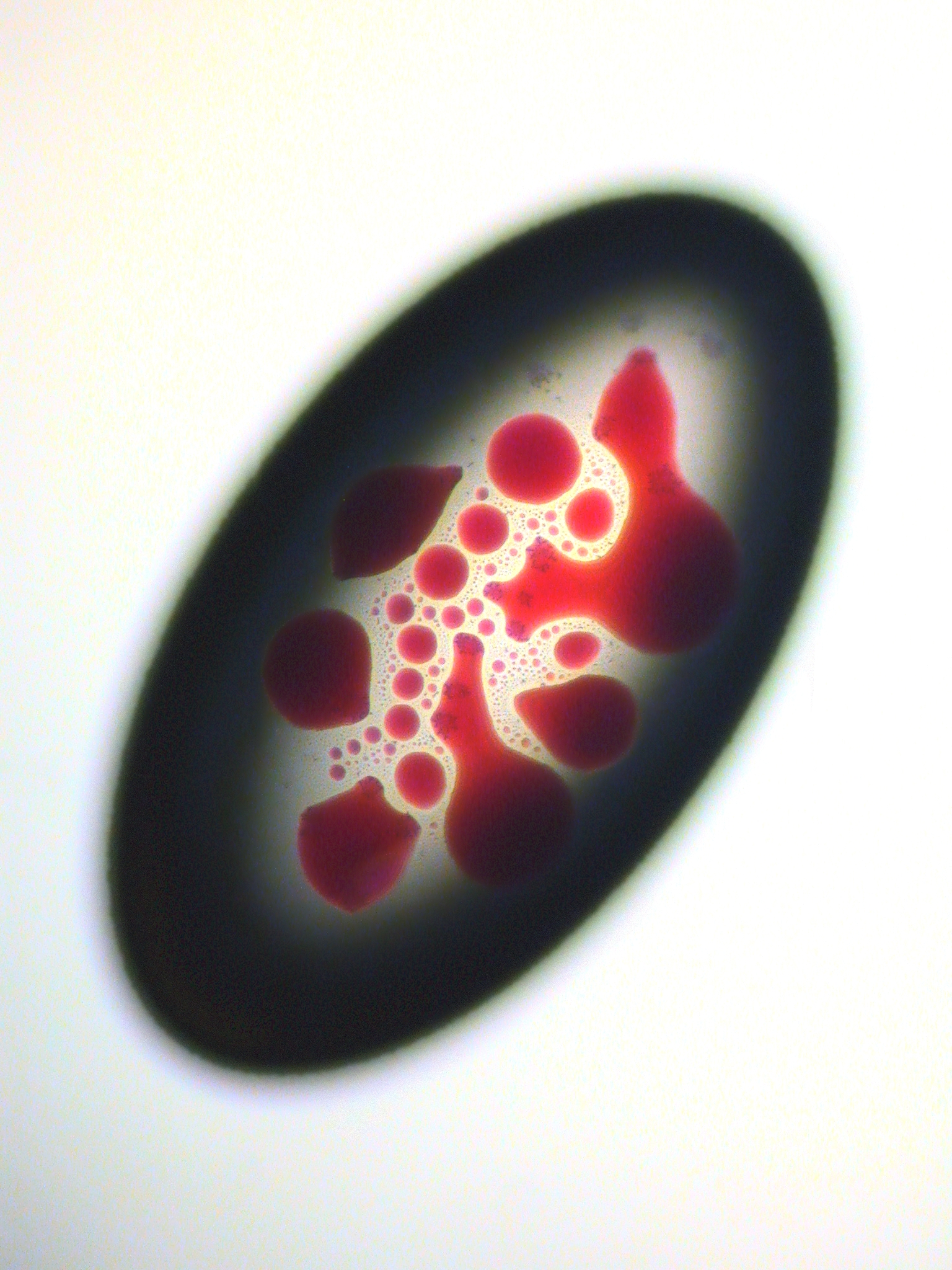

Example: Bubble, containing Selenium

The picture, ordinary passing through light, shows a bubble containing Selenium.

Some bubbles contain also deposits like Selenium or Sulphur. It is essential to analyze these solid inclusions which, again, help to identify possible bubble source with more accuracy.

Example: Stone from fused cast AZS refractory

This electron microscope image shows section of a stone originating in fused-cast AZS refractory. Typical structure of the fused-cast AZS material is preserved in this stone – primary Zirconia grains, primary tabular Corundum crystals and very fine columnar Zirconia crystals grown inside the Corundum.

Example: Chromite stone

Section of a Chromite stone viewed under optical microscope in sideways light and transmitted polarized light is shown in this picture. Residue of the original Chromite particle is surrounded by laths of secondary greenish light-reflecting Escolaite.

Example: Cord

In this picture, cross-section of a cord with stress viewed under optical microscope in transmitted polarized light is displayed.

Example: Gall

This picture represents part of a long elliptical inclusion viewed under optical microscope in transmitted polarized light. The defect is present in a form of a blister filled with condensed Sulphates.

Example: Knot

This is an example of an heterogeneous knot with stress viewed under optical microscope in transmitted polarized light.

Example: Surface defect

This picture shows part of a tin bath related brownish defect found on the bottom surface of the float glass sheet. The surface defect is viewed under optical microscope in transmitted light.

Further Information:

-

Please contact us to receive more information, our latest presentation, or a quotation to purchase.