Hand Made Production Furnaces

GS specializes in the design and construction of the following hand made production furnaces:

- Single pot electric furnaces

- Double pot electric furnaces

- Crucible electric furnaces

- Reheating furnaces

Single pot electric furnaces

The pot furnace is made of high quality refractory materials resistant to exposure to high temperatures and exposure to chemical reactions accompanying the melting of glass.

The maximum required temperature is 1470 °C.

The normal melting temperature of the molten glass is to 1450 °C.

The melting and working cycle is 24 hours typically.

The workspace is equipped with a pot with a theoretical volume up to 330 l.

The most commonly used material of the pot is fireclay, but the furnace is adapted to use the glass pot of another material according to the customer’s requirement (the clay pot will be taken out form the preheating furnace and placed into the furnace at temperature 1200 °C).

The furnace is controlled by automatic controller or PLC.

The furnace is heated by resisting heating elements.

The furnace is not designed for production of glass containing Cl, F and P.

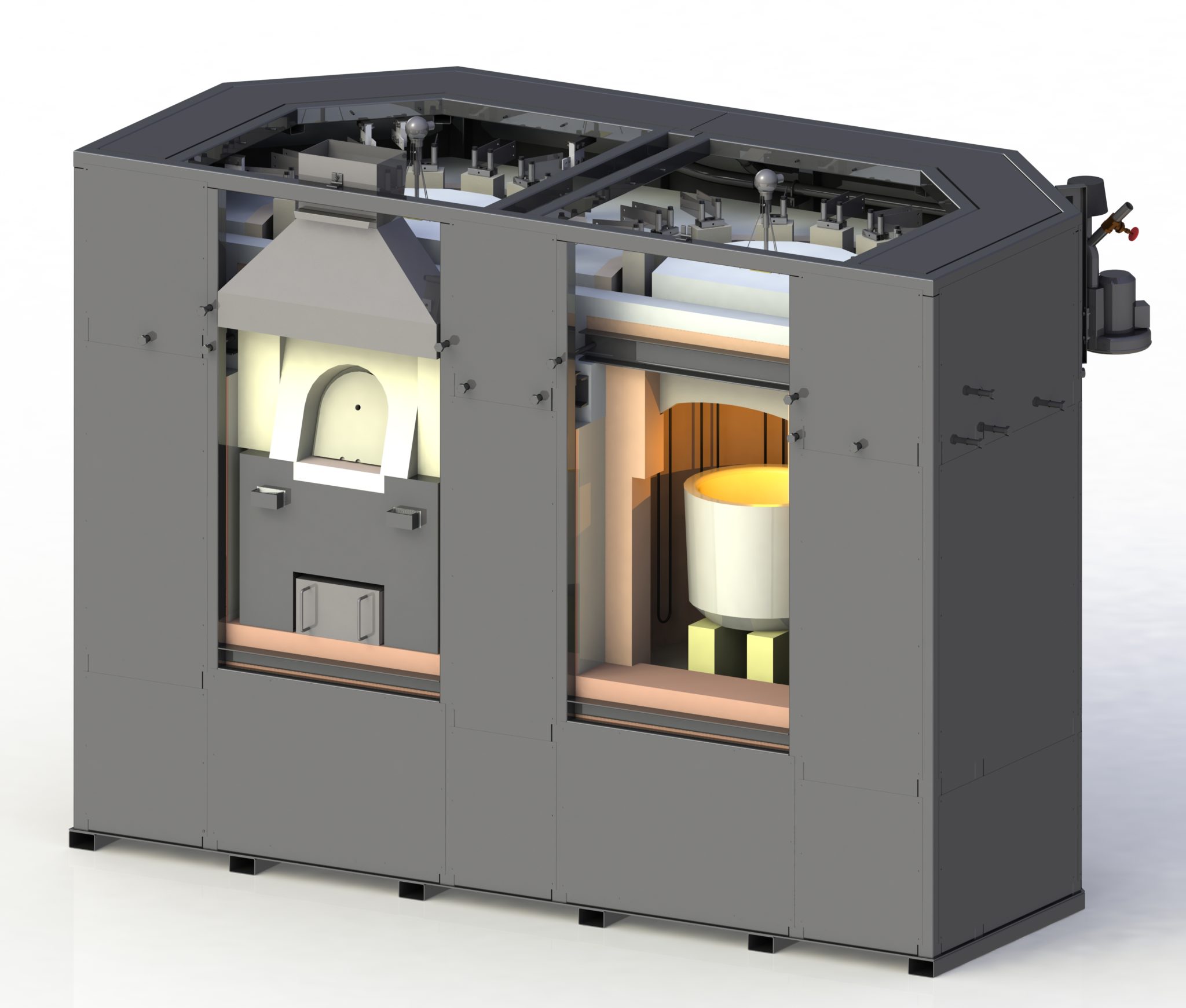

Double pot electric furnaces

The pot furnace is made of high quality refractory materials resistant to exposure to high temperatures and exposure to chemical reactions accompanying the melting of glass.

The working space is divided into two separate parts. In each section, there is possible to maintain the required temperature according to current needs (it is possible to melt the enamel in one part and keep the temperature for glass processing in the second part).

The maximum required temperature is 1470 °C.

The normal melting temperature of the molten glass is to 1450 °C.

The melting and working cycle is 24 hours typically.

Each workspace is equipped with a pot with a theoretical volume up to 330 l.

The most commonly used material of the pot is fireclay, but the furnace is adapted to use the glass pot of another material according to the customer’s requirement (the clay pot will be taken out form the preheating furnace and placed into the furnace at temperature 1200 °C).

The furnace is controlled by automatic controller or PLC.

The furnace is heated by resisting heating elements.

The furnace is not designed for production of glass containing Cl, F and P.

Crucible electric furnaces

The studio-style HOBBY FURNACE II is designed for small-scale glass production needs, as well as for instructional and teaching purposes in the melting of glass.

Maximal melting temperature: up to 1420 °C for standard furnace design

Typical capacity of the crucible: 30 l

Reheating furnaces

The reheating furnaces are used for total or partial heating and polishing of glass products in handmade glass production.

The furnace consists of mobile steel chassis, heating muffle, heating system and safety train. The heating muffle comprises steel frame, steel covering jacket, ceramic fiber lining and multilayer bottom. The bottom consists of refractory slices, high temperature insulation concrete and three ceramic fiber board layers. A support for blowpipe and protection of glass adjustable holder are parts of chassis. The ceramic burners are fixed into a special holder, which secures solid and gas proof connection to supply piping. The burner flame is routed to furnace bottom. Combustion air supplies a medium blower located on the chassis. The main parts of safety train are gas pressure controller, combustion mixture pressure controller and solenoid valve. These parts are connected to the electrical cabinet.

Further Information:

-

Please contact us to receive more information, our latest presentation, or a quotation to purchase.